Product development, like any other complex group endeavor, can be conducted in many different ways. And, like other complex endeavors, product development benefits greatly from adherence to a proven process. While the nature and technology of products may differ greatly, the steps leading to their successful development do not. An effective product development process starts with ideas or visions and ends with the documentation required to manufacture products that fulfill the visions and make money for their companies. At Smart Nanos, Product Development Services, we have always found success in the classic model for product development that includes the following phases:

Product development, like any other complex group endeavor, can be conducted in many different ways. And, like other complex endeavors, product development benefits greatly from adherence to a proven process. While the nature and technology of products may differ greatly, the steps leading to their successful development do not. An effective product development process starts with ideas or visions and ends with the documentation required to manufacture products that fulfill the visions and make money for their companies. At Smart Nanos, Product Development Services, we have always found success in the classic model for product development that includes the following phases:

- Requirements

- Conceptual Design

- Detailed Design

- Design Verification

- Pre-Production

Requirements Phase

The Requirements Phase consists of learning and understanding the product, its value proposition, its competition and, identifying the essential factors that will make it successful in its target market. The culmination of this phase is the joint approval of a Requirements Document by marketing, manufacturing and engineering. These Requirements identify and define the functional, physical and other essential characteristics of the new product. This document typically identifies ‘what’ the product needs to be or do without regard to ‘how’ the requirements are ultimately satisfied. The importance of requirements is frequently misunderstood or even entirely overlooked. Requirements establish the foundation for all the conceptualizing, design, fabrication, testing and documentation that will follow. Failure to clearly identify and articulate the requirements at this stage inevitably leads to cost and schedule consequences at best and, at worst, product failure in the market.

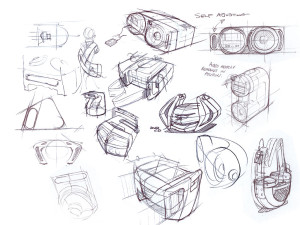

Conceptual Design Phase

The Conceptual Design Phase consists of translating all of the requirements into one or more design concepts. More specifically, this is the first step in the transformation from ‘what’ the product will be to ‘how’ the product will be designed. For example, it may include converting the requirement for a “simple and intuitive” user interface into graphical designs, logic flows and content or possibly switches and indicators as the case may be. It includes the creativity and brainstorming required to identify innovative and efficient ways of satisfying the sum total of the requirements. It is also the point at which invention is differentiated from engineering and either reduced to practice or backed up with a proven contingency. This phase concludes with the approval of a high-level conceptual design that identifies the various technologies required in final design, how they interact with each other and at least one credible means of implementing them to achieve the product. Failure to generate a conceptual design and address any necessary inventions that may be required is critical flaw in product development that can undermine the success of the entire project.

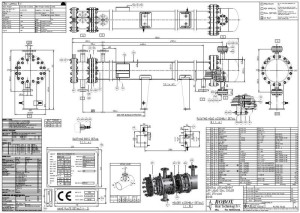

The Detailed Design Phase is where the product takes on physical form; design specifications are generated, the system design is completed, algorithms are developed, software is designed and coded, hardware is designed, simulated and prototyped, mechanisms are modeled and fabricated, prototypes are assembled, the system is integrated, functional testing is performed and design iterations and refinement occur. This is the stage at which the most visible and prolonged activity takes place, the development team tends to be the biggest, and the project spend rate is the highest. Consequently, many inexperienced product development teams view this stage as ‘product development’ in its entirety. An undesired consequence of this distorted view is minimizing or even ignoring the prior or subsequent phases. However, entering into Detailed Design without clearly articulated and documented requirements and a conceptual design is the recipe for an expensive and prolonged product development failure. The output of this phase is an unvetted set of controlled documents, which if followed correctly, will produce a product that meets the functional requirements.

The Design Verification Phase includes comprehensive testing and approval of the product and its design. The product is rigorously tested to confirm that all physical and functional requirements are satisfied from their minimum to their maximum limits. The product is also tested against fitness-for-use requirements: Do unbiased, non-team members confirm that it is intuitive and easy to use? Can they induce unintended results by using the product in an unanticipated manner? Does it pass certification testing by independent agencies? Most importantly, the design documentation package, which represents the ultimate deliverable of the product development process, is thoroughly reviewed, vetted and approved. This stage is often over looked or minimized because, at the end of the Detailed Design phase , the product apparently ‘worked’ or at least satisfied many of its functional requirements. However, failure to conduct a thorough DVT at this stage always costs more and takes longer than moving project on to Pre-Production with insufficient confirmation.

The Pre-Production Phase is the culmination of the product development process and final confirmation of the phases that precede it. This phase includes the tasks of generating and confirming the manufacturing process and test documentation so that the product can be produced by any experienced manufacturing organization. Many fail to appreciate the fact that the primary deliverable of the product development process is the documentation required to manufacture that product and not the product per se. Consequently, successful conclusion of the Pre-Production Phase and this product development process provides an affirmative answer to ultimate product development question:

Does the design documentation package include all the information required to successfully produce the product that satisfies the requirements?

Contact us to learn more about our product development process.